-

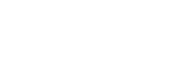

High Quality QLQ Wholesale Custom Auto-lock zipper slider body mould China Factory, Zipper Slider Mould, Zipper Machine Factory

Key attributes

Industry-specific attributes

| Shaping Mode | Die Casting |

Other attributes

| Place of Origin | Guangdong, China |

| Brand Name | QLQ |

| Model Number | N/M/D51A |

| Product Material | metal |

| Product | Vehicle Mould |

Packaging and delivery

| Packaging Details | Standard export packing |

| Selling Units | Single item |

| Single package size | 25X25X35 cm |

| Single gross weight | 50.000 kg |

What slider moulds do you want to buy?Does your mould have these problems?

Six Characteristics of A Good Slider Mould.

1-Precise size, well-pieced mould core,Precise size assures zipper smoothness, good locking, high strength and no zipper abnormality. 2-Good-quality material, FDAC and DAC steel imported from Japan,Wearing resistance, good tenacity, long life.

2-Good-quality material, FDAC and DAC steel imported from Japan,Wearing resistance, good tenacity, long life.

3-High precision of mould, tolerance controlled at ± 0.02MM.

4-Full and bright casting, without burrs,Make pre-treatment easy and save cost.

5-Strict delivery inspection

Each set of moulds shall be tested at least 1000 cavities, and shall be inspected and signed by chief designer, factory manager and die casting master together before delivery.

6-A whole set of technical support for slider manufacturing

We provide one-stop service to the customers to produce high-quality sliders from die casting attentions, mould maintenance and repair, product polishing, slider assembly, plating.

| Brief description | CNC Machines,Lathe Machine,Milling Machine,Punching Machines,Centerless grinding,laser machines,etc. |

| Article name | QLQ casting mould,injection mould,custom different type mould. |

| Surface treatment | polish / plating / powder coating / painting,and so on,as you request |

| MOQ | 1set |

| Lead-time | 4-7 weeks |

| Package | Wooden/plywood case for tool. PE bags and Export Carton for parts |

| Export Country | Europe, Mexico, Russia, Australia, Middle-East, Asia etc |

About our Factory workshop&Office

Q:What kind of pressing mold can QLQ supply?

A:YG slider body mold, YG slider spring mold, YG slider puller mold, slider needle/monkey mold, slider spring mold, hook mold, flat/middle puller mold, etc. Our mold factory with more than 15 years design & manufacturing experience.

Q:What is the using life of QLQ moulds?

A:Normally, the mould can be made 1,000,000 times if your company can protect the mould carefully. For example, clear the mould frequently when your technician use the mould and put some "release agent" in the mould. If your company doesn't have the slider order, you should clean the mould and put some antirust oil in the mould to protect it. Normally, after 1000000 times, maybe the mould frame or mould heart has been worn, the mould can be continue used about 1,000,000 times again after you repair it.

Q:I want to buy moulds for auto-lock slider, can you design the size as per my zipper?

A:Yes, we have a professional team, and our engineer has more than 20years experience, we can design the slider size as per your requirement.

Q:Can QLQ mould factory produce the invisible slider body moving core for us although our slider body mould was not made from your side before?

A:Yes, of course, pls send the drawing of your moving core and at least 1 piece of moving core sample to us, we can make the same for you according to your drawing and sample.

Q:Can I make a plastic teeth injection mould with different teeth shapes on two sides?

A:Yes, we can do so if the shape of zipper teeth is nearly alike in their size. You can firstly send us your zipper teeth pictures/drawings, then our technician will analyze whether they can work on the same plastic zipper or not.

Contact us for more information!

| Name | Cathy Li |

| Mobile | 0086-13316184685/13809668444 |

| Wechat/Whatsapp | 0086-13316184685/13809668444 |

| Tell | 0086-20-89689081 |

| Web | www.zippermachine.com/www.qlqcompany.com |

Related Products

-

Precio De Zippers Rainbow Color Nylon Zipper Logo For Shoes Tirador De Cremallera Custom Ready Made Zipper 30cm 40cm Nylon Zips

Precio De Zippers Rainbow Color Nylon Zipper Logo For Shoes Tirador De Cremallera Custom Ready Made Zipper 30cm 40cm Nylon Zips

-

Waterproof Film

Waterproof Film

-

Sewing Thread (suitable for sewing zipper tape & monofilament chain)

Sewing Thread (suitable for sewing zipper tape & monofilament chain)

-

Single Twisted Centre Cord

Single Twisted Centre Cord

-

Factory Price Wholesale 3 5 810 Metal Zipper for Garment Bags Shoes Zipper Charm Brass Aluminum Long Chain Metal Zipper

Factory Price Wholesale 3 5 810 Metal Zipper for Garment Bags Shoes Zipper Charm Brass Aluminum Long Chain Metal Zipper