-

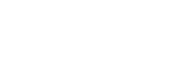

Automatic Gapping Machine for Nylon Zipper Gapping Machine Single Blade Nylon Zipper Gaping Top and Bottom Lock Machine

Key attributes

Other attributes

| Applicable Industries | Manufacturing Plant |

| Showroom Location | Bangladesh |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | New Product 2020 |

| Warranty of core components | 1 Year |

| Core Components | PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump |

| Place of Origin | Guangdong, China |

| Weight | 400 KG |

| Warranty | 2 years |

| Condition | New |

| Brand Name | QLQ |

| Voltage | 220v |

| Dimension(L*W*H) | 0.7*0.8*1.5 (m) |

| Zipper Material | nylon |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Product type | Gapping and Trimming Machine |

| After Warranty Service | Video technical support |

Packaging and delivery

| Packaging Details | Standard export packing |

| Port | Shenzhen |

| Selling Units | Single item |

| Single package size | 155X95X180 cm |

| Single gross weight | 400.000 kg |

Supply Ability

| Supply Ability | 50 Set/Sets per Month 50 sets

|

|

MODEL NO.

|

QLQ-NDGBM-1

|

N.W(KG)

|

340

|

M/C SIZE(CM)

|

140*80*150

|

|

AVG.OUTPUT

|

3600PCS/18CM/H

|

G.W(KG)

|

400

|

PKGS SIZE(CM)

|

155*95*180

|

|

VOLTAGE(V)

|

220V

|

POWER??KW)

|

2.0

|

PHASE(PH)

|

1

|

Machine Advantages:

Related Products

2-- Do you have finished zipper machines?

QLQ: Yes, we have zipper machines for the whole production line, open-end finished zipper and closed-end finished zipper.

QLQ: After you confirm the order, you need to tell us the size you need, then we will need you to arrange the zipper and the slider of the samples to us, we will check and to make the machines according to your samples, when the machines are ready, we will use your samples to test the machines, and then we will send these samples to you check. If you confirm the samples, we can arrange shipment for you.

Related Products

-

Top Stop Wire(material:brass,aluminum which can be plated to be black nickel,brass,antique brass and other colors)

Top Stop Wire(material:brass,aluminum which can be plated to be black nickel,brass,antique brass and other colors)

-

Metal Teeth Nickel Zipper Tape Open End Aluminum Zipper Rolls For Handbag Concealed Zip Roll Long Chain Metal Zipper

Metal Teeth Nickel Zipper Tape Open End Aluminum Zipper Rolls For Handbag Concealed Zip Roll Long Chain Metal Zipper

-

Elastic Zipper Factory Wholesales Open End Custom Kcc Nylon Zipper For Sofa Bag Bedding #5 #7 Finished Nylon Zipper Pouch

Elastic Zipper Factory Wholesales Open End Custom Kcc Nylon Zipper For Sofa Bag Bedding #5 #7 Finished Nylon Zipper Pouch

-

Stainless Steel Zip Roll Zipper Metallic Continuous For Bag Long Chain Brass Bag Pull Yard Zipper Tape Copper Coil Metal Zipper

Stainless Steel Zip Roll Zipper Metallic Continuous For Bag Long Chain Brass Bag Pull Yard Zipper Tape Copper Coil Metal Zipper

-

Double Twisted Centre Cord

Double Twisted Centre Cord