-

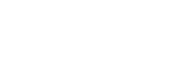

Hand Operated Zinc Alloy Snap Button Making Die Casting Machine Automatic for Zinc Glass Accessories Button Making Machines

Key attributes

Other attributes

| Machine Type | Hot Chamber Die Casting Machine |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | New Product 2020 |

| Warranty of core components | 1 Year |

| Core Components | PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump |

| Place of Origin | Guangdong, China |

| Condition | New |

| Weight (KG) | 500 |

| Warranty | 1 Year |

| Key Selling Points | Automatic |

| Applicable Industries | Energy & Mining, Machinery Repair Shops |

| Showroom Location | Italy |

| Max.Thickness of Die Block (mm) | 100 mm |

| Min.Thickness of Die Block (mm) | 100 mm |

| Ejection Force(kN) | 1 kN |

| Ejection Stroke(mm) | 1 mm |

| Brand Name | QLQ |

| Voltage | 380V |

| Dimension(L*W*H) | 2.1x1.2x2.3m |

| Power (kW) | 2 |

| Product type | Casting Machine |

| Power(W) | 1.6KW |

| Weight | 800Kg |

| After-sales Service Provided | No after-sales service |

Packaging and delivery

| Packaging Details | Standard export packing |

| Port | GUANGZHOU |

| Selling Units: | Single item |

| Single package size: | [Insert single package size here] |

| Single gross weight: | 800 kg |

Supply Ability

| Supply Ability | 1 Set/Sets per Day |

performance.

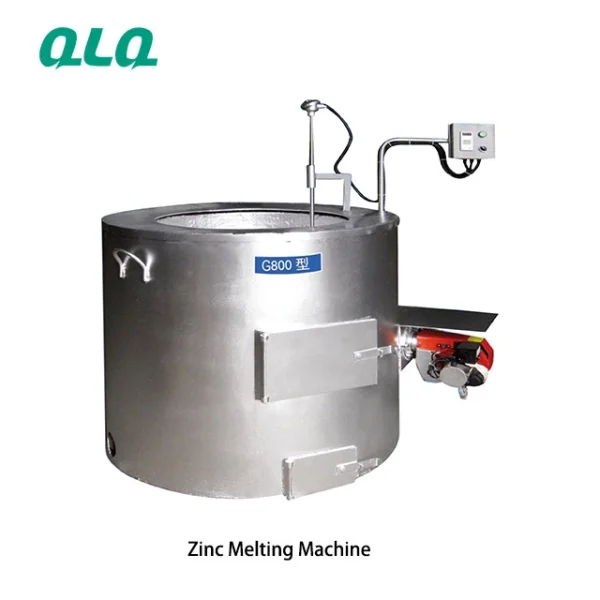

2- Our die-casting machine adopts automatic oil supply system and the steel pins and tie bats are not easy to broken. It adopts

buckle nozzle cylinder to increase working efficiency.

Third advantage

3-By adopting jogging mould locking and mould opening,this machine is more sate to be operated.

|

Which ton I want

|

15 Ton

|

25 Ton

|

30 Ton - 50 Ton

|

30 Ton - 50 Ton

|

|

Suitable items

|

slider, puller, small button ( mould is small). spead is fast

|

Mould is more bigger, output is more

|

spead is not so fast, mould is big,output is more much

|

for big products, bag hardware

|

report before shipment.

1. Should I choose how many ton die casting machine?

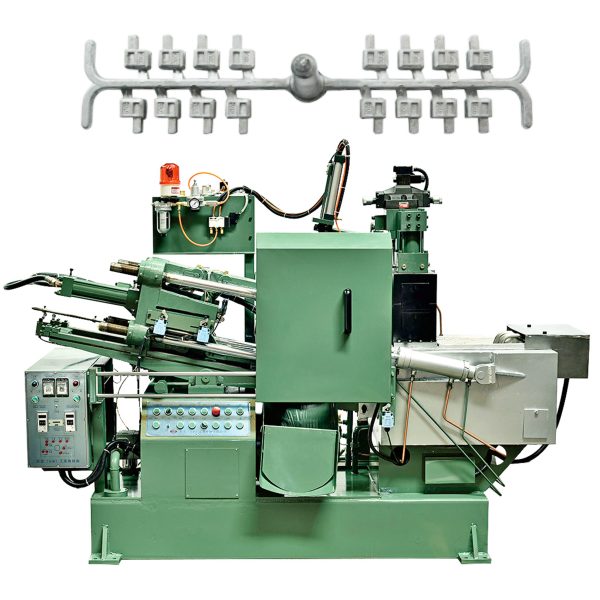

2. What is the heating way of your die casting machine?

3. I want to buy spare parts of die casting machine, can you offer to me?

4. What product can be made on this machine?

Related Products

-

QLQ-AMPM Automatic Mould Pressing Machine

QLQ-AMPM Automatic Mould Pressing Machine

-

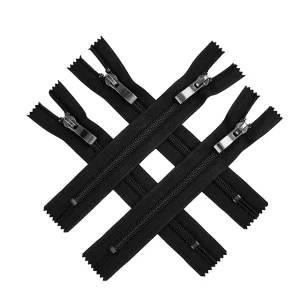

Custom Color Nylon Zipper For Women Jogger Yoga Clothing Doll Mashin Coded Adjustable Comfortable Closed End No 7 Nylon Zippers

Custom Color Nylon Zipper For Women Jogger Yoga Clothing Doll Mashin Coded Adjustable Comfortable Closed End No 7 Nylon Zippers

-

Stainless Steel Zip Roll Zipper Metallic Continuous For Bag Long Chain Brass Bag Pull Yard Zipper Tape Copper Coil Metal Zipper

Stainless Steel Zip Roll Zipper Metallic Continuous For Bag Long Chain Brass Bag Pull Yard Zipper Tape Copper Coil Metal Zipper

-

Stainless Steel Wire (for spring cap of 5 components auto-lock slider)

Stainless Steel Wire (for spring cap of 5 components auto-lock slider)

-

QLQ-SMPM Semi-automatic Mould Pressing Machine

QLQ-SMPM Semi-automatic Mould Pressing Machine