-

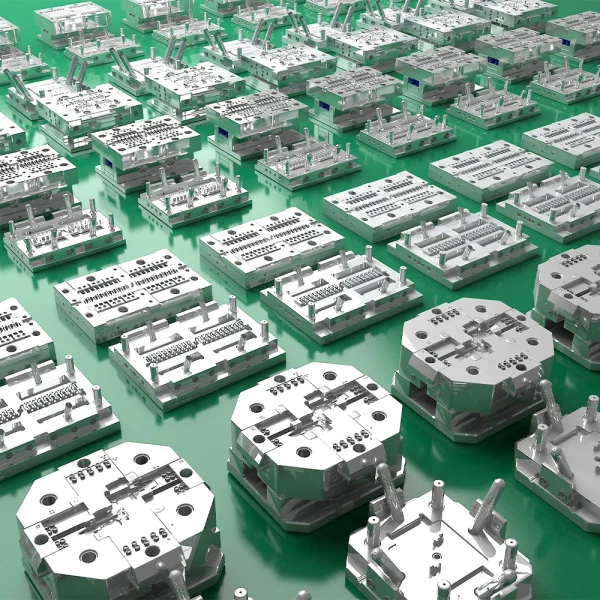

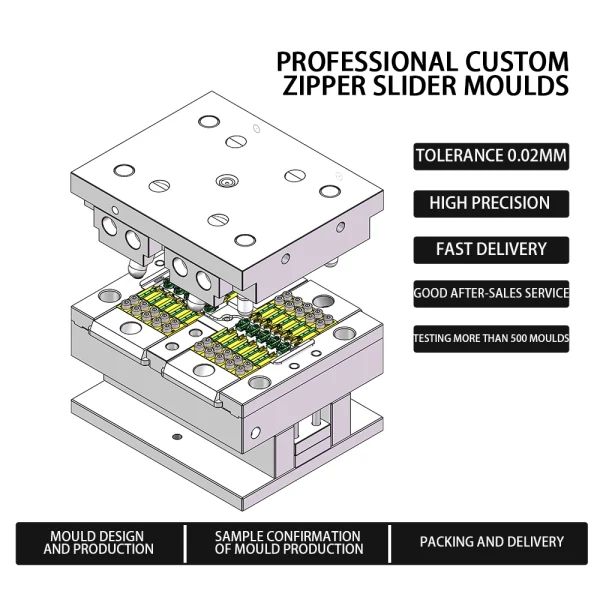

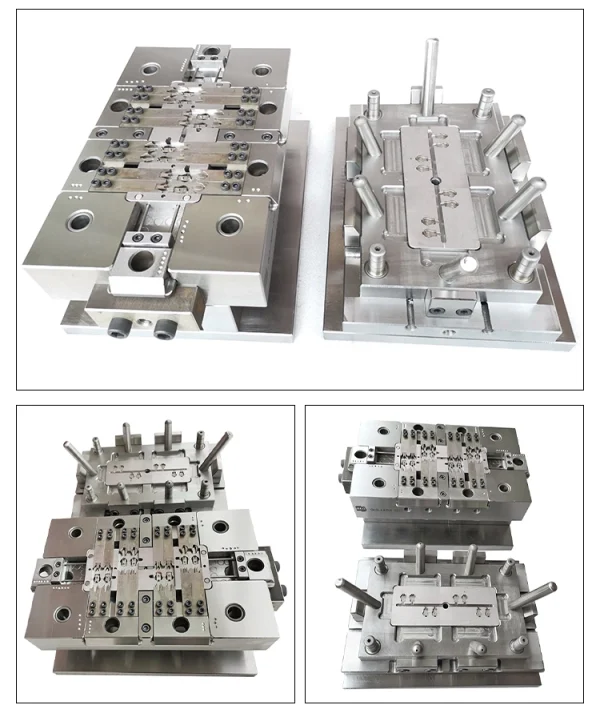

QLQ One-stop service for customized zipper slider body puller hardware Die Casting mould zipper button plastic injection mould

Key attributes

Industry-specific attributes

| Shaping Mode | Die Casting |

Other attributes

| Place of Origin | Guangdong, China |

| Brand Name | QLQ |

| Model Number | zinc casting mould |

| Product Material | zinc |

| Product | slider body |

| Product type | die casting slider mould & Injection mould |

| available cavities | mould can make as per customer requirement |

| mould size | the size will be designed as per customers' machine specification |

| Brand Name | QLQ |

| Place of Origin | Guangdong, China |

| slider mould packing | export standard wood case packing |

| suitable products | auto-lock slider, non-lock slider, Italy slider etc. |

Packaging and delivery

| Packaging Details | standard export packing for die casting slider mould |

| Port | Shenzhen/Guangzhou |

Supply Ability

| Supply Ability | 50 Set/Sets per Month die casting slider mould |

|

Product Name

|

Zipper slider molud,Zipper puller mould,Auto-lock cap mould,Auto-lock slider body mould.Pin-lock slider body mould,Spring-lock sldier body mould,Non-lock slider body mould,Italy type slider body mould,Invisible slider body mould,Pin pinmould,Box mould,Bottom stop mould,Bag hardware mould,Hook mould...

|

|

Type

|

Zinc die casting machine,Injection mould

|

|

Cavities

|

It's customized according to your die casting machine and products.

|

Related Products

-

QLQ-SMPM Semi-automatic Mould Pressing Machine

QLQ-SMPM Semi-automatic Mould Pressing Machine

-

Stainless Steel Zip Roll Zipper Metallic Continuous For Bag Long Chain Brass Bag Pull Yard Zipper Tape Copper Coil Metal Zipper

Stainless Steel Zip Roll Zipper Metallic Continuous For Bag Long Chain Brass Bag Pull Yard Zipper Tape Copper Coil Metal Zipper

-

Multi Colored Nylon Zipper 20# 3# 5# For Clothing Pants Bedding Talon Printed Strip Zipper No 5 Strings Universal Nylon Zipper

Multi Colored Nylon Zipper 20# 3# 5# For Clothing Pants Bedding Talon Printed Strip Zipper No 5 Strings Universal Nylon Zipper

-

Metal Teeth Nickel Zipper Tape Open End Aluminum Zipper Rolls For Handbag Concealed Zip Roll Long Chain Metal Zipper

Metal Teeth Nickel Zipper Tape Open End Aluminum Zipper Rolls For Handbag Concealed Zip Roll Long Chain Metal Zipper

-

Manufacturer Number 5 Small Nylon Zippers For Mattress Draps Roi Taille Sofa Sweatpants Custom Logo Locking Zip Nylon Zipper

Manufacturer Number 5 Small Nylon Zippers For Mattress Draps Roi Taille Sofa Sweatpants Custom Logo Locking Zip Nylon Zipper