-

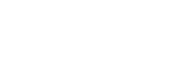

Hot Sale 12t30t20ton automathic horizontal little faucet die casting manual toys making machine medals shell spray head gun used

Key attributes

Other attributes

| Machine Type | Hot Chamber Die Casting Machine |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | New Product 2020 |

| Warranty of core components | 1 Year |

| Core Components | PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump |

| Place of Origin | Guangdong, China |

| Condition | New |

| Weight (KG) | 500 |

| Warranty | 1 Year |

| Key Selling Points | Automatic |

| Applicable Industries | Energy & Mining, Machinery Repair Shops |

| Showroom Location | Italy |

| Max.Thickness of Die Block (mm) | 100 mm |

| Min.Thickness of Die Block (mm) | 100 mm |

| Ejection Force(kN) | 1 kN |

| Ejection Stroke(mm) | 1 mm |

| Brand Name | QLQ |

| Voltage | 380V |

| Dimension(L*W*H) | 2.1x1.2x2.3m |

| Power (kW) | 2 |

| Product type | Casting Machine |

| Power(W) | 1.6KW |

| Weight | 800Kg |

| After-sales Service Provided | Online support |

Packaging and delivery

| Packaging Details | Standard export packing |

MODEL:QLQ-HDCM

30T Automatic Hot Chamber Die Casting Machine

1.With computer controlled system, this die casting machine can store many mould number and also has the fuction of memeory.

2. Adopting computer control for automatic mould adjustment, the machine is easy to operate, which can achieve precision die casting position.

3. The die casting machine is suitable for die casting of non-ferrous metal such as aluminum, zinc and copper.

4. Energy saving with competitive price, which helps you save the cost.

5.Stable performance with stable system, 24 hours continuous running is possible.

6.Satisfied after-sales service.

Main technical data

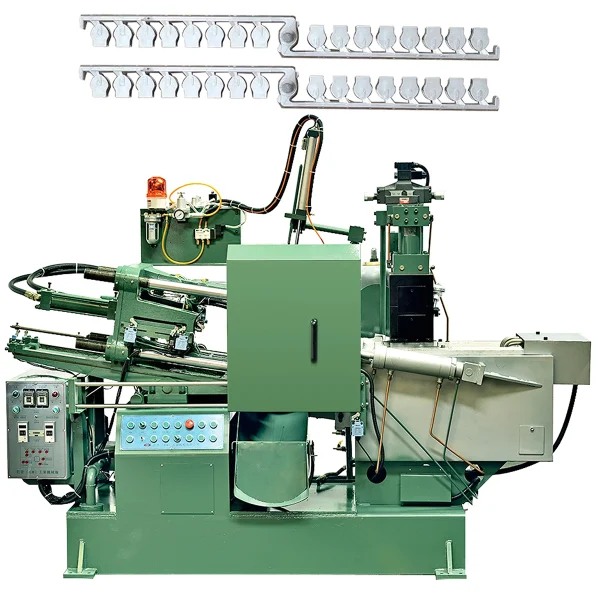

Main technical data| project | Unit | 30T |

| The locking pressure | KN | 30Ton |

| The current capacity of the oil pump | L | RV2R2-53 |

| The capacity of oil tank | L | 350 |

| The nominal pressure | Kg/cm2 | 80 |

| The energy accumulator | L-number | 20L |

| Energy accumulator | kw | 7.5HP(10HP) |

| The size of the inner pillar(mold installed size) | mm | 275*275 |

| The mould-opening stroke | mm | 200 |

| The thickness of the mould(min-max) | mm | 130-280 |

| The tiebar diameter | mm | Φ50 |

| The injecting force | KN | 36 |

| The injecting stroke | mm | 100 |

| The injecting rod diameter | mm | Φ45 |

| The ejection location | mm | 40 |

| The die-casting quantity(reality) | g | 60-350 |

| The injection location | mm | 0 |

| The capacity of the melting pot(zinc) | kg | 150 |

| The center distance of front mold screw | mm | 120 |

Our sales inspect the products to be delivered to assure their good quality and take videos of explaining their operation processes in English for our customers.

Q:What is the most popular die casting machine to produce zinc slider body?

A:OLQ-HDCM automatic hot chamber die casting machine is your best choice. There are 15 tons, 25 tons and 30 tons for your selection.

Q:Is QLQ die casting machine easy for maintenance and what are the easy wearing parts?

A:Our hot chamber die casting machine is easy for maintenance. The easy-wearing parts are zinc melting pot, shooting pole, electric heating pipe, heating sheath, material cup/entrance, nozzle, steel ring/piston ring.

Q:What are your companys advantages?

A:Firstly, we are very professional and have experienced cooperators; most of them are in zipper and slider business line for more than 15 years. Besides, our customers can enjoy high efficiency, That is to say, we will do almost all things for our clients and all they need to do is to contact us. Also, we offer our customers best price, quality inspection and marvelous after-sale service.

Q:How about your after-sale service?

A:We can send our technicians abroad to train your workers and give you technical support.

Contact us for more information and the latest price!

Related Products

-

Slider Pressing Part

Slider Pressing Part

-

Elastic Zipper Factory Wholesales Open End Custom Kcc Nylon Zipper For Sofa Bag Bedding #5 #7 Finished Nylon Zipper Pouch

Elastic Zipper Factory Wholesales Open End Custom Kcc Nylon Zipper For Sofa Bag Bedding #5 #7 Finished Nylon Zipper Pouch

-

Golden Metal Zipper For Overcoat Coat Jacket Gold Coil Brown #5 Zip Tape Iron Solid Antique Brass Long Chain Metal Zipper Roll

Golden Metal Zipper For Overcoat Coat Jacket Gold Coil Brown #5 Zip Tape Iron Solid Antique Brass Long Chain Metal Zipper Roll

-

Stainless Steel Zip Roll Zipper Metallic Continuous For Bag Long Chain Brass Bag Pull Yard Zipper Tape Copper Coil Metal Zipper

Stainless Steel Zip Roll Zipper Metallic Continuous For Bag Long Chain Brass Bag Pull Yard Zipper Tape Copper Coil Metal Zipper

-

Waterproof Film

Waterproof Film