-

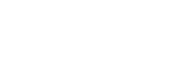

12 20 30 ton Hot Chamber Metal Zipper Hardware Accessories Pressure Oven Die Casting Molding Press Machine 15t Parts for Zipper

Key attributes

Other attributes

| Machine Type | Hot Chamber Die Casting Machine |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | Ordinary Product |

| Warranty of core components | 2 years |

| Core Components | Engine, Motor, Gear, Pump |

| Place of Origin | Guangdong, China |

| Condition | New |

| Weight (KG) | 900 |

| Warranty | 2 years |

| Key Selling Points | Automatic |

| Applicable Industries | Manufacturing Plant, zinc products |

| Showroom Location | Canada, Turkey, United Kingdom, Peru, Indonesia, Pakistan, Russia, Spain |

| Max.Thickness of Die Block (mm) | 280 mm |

| Min.Thickness of Die Block (mm) | 100 mm |

| Ejection Force(kN) | 100 kN |

| Ejection Stroke(mm) | 200 mm |

| Brand Name | QLQ |

| Voltage | 380V |

| Dimension(L*W*H) | 2.7*1.2*2.3m |

| Power (kW) | 15kw |

| Product type | Znic Hot Chamber Die Casting Machine |

| Function | only for zinc die casting |

| Model | 15T/25T/30T |

| Certification | CE |

| Frequency | 50HZ |

| Power | 21kw |

| Weight | 800kg |

| Phase | 3PH |

| Die thickness(min~max) | 25KN |

| Core Components | PLC,Pump |

Packaging and delivery

| Packaging Details | Standard export packing |

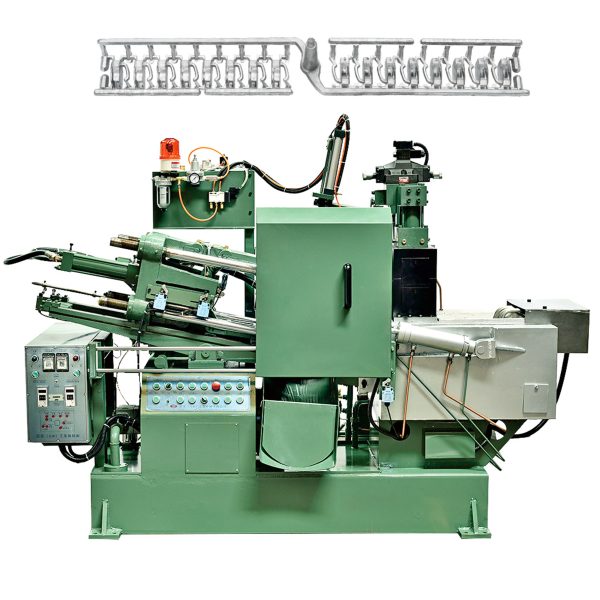

2- Our die-casting machine adopts automatic oil supply system and the steel pins and tie bats are not easy to broken. It adopts buckle nozzle cylinder to increase working efficiency.

3- By adopting jogging mould locking and mould opening, this machine is more safe to be operated.

|

Which ton I want

|

15 Ton

|

25 Ton

|

30 Ton - 50 Ton

|

30 Ton - 50 Ton

|

|

Suitable items

|

slider, puller, small button ( mould is small). spead is fast

|

Mould is more bigger, output is more

|

spead is not so fast, mould is big,output is more much

|

for big products, bag hardware

|

|

Item

|

Unit

|

15T

|

25T

|

30T

|

|

Mould clamoing pressure

|

KN

|

150

|

250

|

300

|

|

Oil pump flow

|

L

|

PV2R2-33

|

PV2R2-47

|

PV2R2-53

|

|

Oil drum capacity

|

L

|

180

|

250

|

350

|

|

Rated pressure

|

Kg/c?O

|

50

|

80

|

80

|

|

Energy accumulator

|

L

|

10L

|

16L

|

20L

|

|

Motor power

|

Kw

|

5.5HP

|

7.5(10HP)

|

7.5(10HP)

|

|

Tie bars diameter (for fixing mould)

|

MM

|

210x210

|

230x230

|

270x270

|

|

Casting force

|

MM

|

15

|

15

|

30

|

|

Casting stroke

|

MM

|

80

|

80

|

100

|

|

Opening stroke

|

MM

|

135

|

170

|

200

|

|

Mould thickness (min-max)

|

MM

|

120-180

|

100-270

|

100-280

|

|

Tie bars diameter

|

MM

|

φ35

|

φ45

|

φ50

|

|

Ejection bar diameter

|

MM

|

φ35

|

φ38

|

φ45

|

|

Shooting pole diameter

|

MM

|

φ38

|

φ30

|

φ40

|

|

Casting capacity (actual)

|

G

|

60-120

|

60-180

|

60-350

|

|

Ejection position

|

MM

|

0

|

0

|

0

|

|

Zinc melting pot capacity

|

Kg

|

120

|

150

|

150

|

|

Centre distance of front mould screw

|

MM

|

120

|

120

|

120

|

report before shipment.

1. Should I choose how many ton die casting machine?

Related Products

-

Top Stop Wire(material:brass,aluminum which can be plated to be black nickel,brass,antique brass and other colors)

Top Stop Wire(material:brass,aluminum which can be plated to be black nickel,brass,antique brass and other colors)

-

Sewing Thread (suitable for sewing zipper tape & monofilament chain)

Sewing Thread (suitable for sewing zipper tape & monofilament chain)

-

Waterproof Film

Waterproof Film

-

Metal Teeth Nickel Zipper Tape Open End Aluminum Zipper Rolls For Handbag Concealed Zip Roll Long Chain Metal Zipper

Metal Teeth Nickel Zipper Tape Open End Aluminum Zipper Rolls For Handbag Concealed Zip Roll Long Chain Metal Zipper

-

Slider Pressing Part

Slider Pressing Part