-

QLQ-NDGM-2 Automatic Nylon Zipper Double Trimming Gapping M/C - Machine (short model)

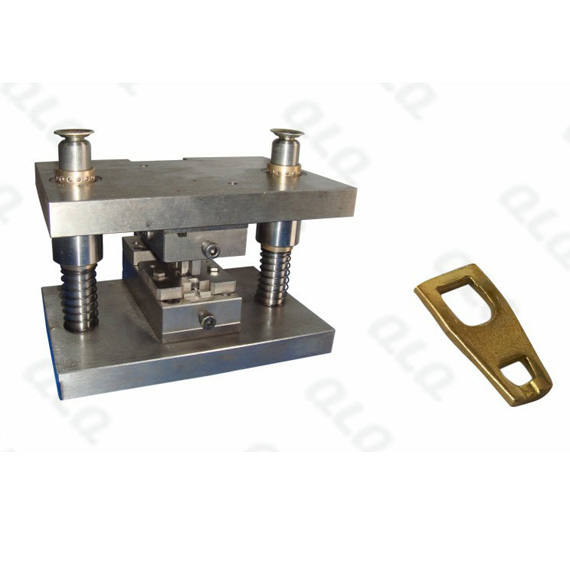

Summary : Using the gapping mould of 2 sides, 4 needle hooks, so that there is almost no need to clean the half teeth on two sides of zippers because only 0.2% of zippers will have half teeth.

Product Name: Automatic Nylon Zipper Double Trimming Gapping Machine (short model)

Model number : QLQ-NDGM-2

Summary : Using the gapping mould of 2 sides, 4 needle hooks, so that there is almost no need to clean the half teeth on two sides of zippers because only 0.2% of zippers will have half teeth.

| Products Features | High Configuration Plus(+) Model | Standard Configuration Model |

| Picture |

|

|

| Air Switch | Japanese Fuji | Delixi |

| Cylinder | Japanese SMC | AirTAC |

| Magnetic Value | Japanese SMC | AirTAC |

| Air Pressure Filter | Japanese SMC | AirTAC |

| 24-V Power Supply | OMRON | Mingwei |

| Zipping Guiding frame | Oxidized Aluminium Pipe + Extra thick zipper guiding wheel | Normal |

| Line Bank | Pure Copper | Plated Copper |

| Relay | Omron | AIKS / CHINT |

| Machine Body | Aluminium Alloy | Normal Iron frame |

| Wheel | With Four Wheels | Withour Four Wheels |

| Material Frame | Aluminium Alloy | Normal Iron |

| Advantages |

1) Using the gapping mould of 2 sides, 4 needle hooks, so that there is almost no need to clean the half teeth on two sides of zippers because only 0.2% of zippers will have half teeth. 2) By adopting touch screen control, customers can adjust the machine gapping speed and gapping empty length election. 3) By adopting servo motor gapping without hooked needle gapping, the distance between gapping mould and tape pulling part is very short. By this short distance, zipper length's tolerance will be less, so this machine is more suitable for the zipper length less than 5cm And later than 100cm for getting more correct zipper length. But if customers want to make 15cm-100cm zipper, it is better to choose our QLQ-NGMC-1.

|

|

Chat Now!

Chat Now!