-

QLQ-NDGM-1 Automatic Nylon Zipper Double Trimming Gapping M/C - Machine (long model)

Summary: Using the gapping mould of 2 sides, 4 needle hooks, so that there is almost no need to clean the half teeth on two sides of zippers because only 0.2% of zippers will have half teeth.

Product Name: Automatic Nylon Zipper Double Trimming Gapping Machine (long model)

Model number : QLQ-NDGM-1

Summary : Using the gapping mould of 2 sides, 4 needle hooks, so that there is almost no need to clean the half teeth on two sides of zippers because only 0.2% of zippers will have half teeth.

| MODEL NO: |

QLQ-NDGM-1 |

Export Packing: | plywood packing | Touch Screen Control: | YES |

| MOQ: | 1 Set | Gapping Mould Sides: | 2 Sides | ||

| Lead time: | 30 days | Needle Hooks: | 4 |

|

|

| Products Features | High Configuration Model | Standard Configuration Model |

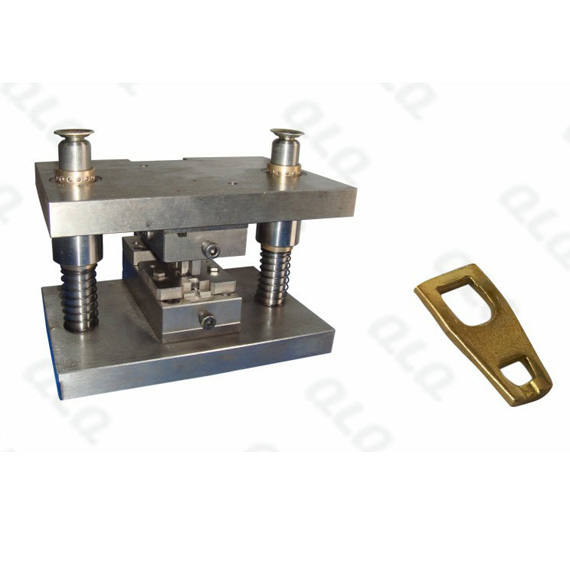

| Picture |

|

|

| Air Switch | Japanese Fuji | Delixi |

| Cylinder | Japanese SMC | AirTAC |

| Magnetic Value | Japanese SMC | AirTAC |

| Air Pressure Filter | Japanese SMC | AirTAC |

| 24-V Power Supply | OMRON | Mingwei |

| Zipping Guiding frame | Oxidized Aluminium Pipe + Extra thick zipper guiding wheel | Normal |

| Line Bank | Pure Copper | Plated Copper |

| Relay | Omron | AIKS / CHINT |

| Machine Body | Aluminium Alloy | Normal Iron frame |

| Wheel | With Four Wheels | Withour Four Wheels |

| Material Frame | Aluminium Alloy | Normal Iron |

| Advantages |

1-Using the gapping mould of 2 sides, 4 needle hooks, so that there is almost no need to clean the half teeth on two sides of zippers because only 0.2% of zippers will have half teeth. 2- By adopting touch screen control, customers can adjust the machine.

|

|

Chat Now!

Chat Now!