——Jun 10, 2019Lock vs Non-Lock Zipper Sliders

Zipper Sliders are very important when it comes to zipper manufacturing. Zipper Slider is a component which opens or closes the zipper. Based on zipper type there are several types of sliders you can choose from. But you will have to be careful when you are choosing the slider, because if we choose wrong type of slider the zippers will not work properly.

According to different zipper types you will find different sliders like metal, plastic, nylon, coil zipper sliders. But zipper sliders have not only those classifications, we can mark it according to locking system also. Zipper locking system means, a system which will not move the zipper position. For instance, if we use lock feature to our slider it will remain same position all the time. In this article, we will discuss about the difference between Auto lock and Non-lock sliders and how you can choose best one for your zipper manufacturing.

If we compare the locking system of zipper sliders then there are exactly 3 types of sliders.

1. Auto lock Slider

- 5 Component Auto lock

- 3 Component Auto lock

2. Semi Auto lock Slider

3. Non-lock Slider

All of those slider types are used in different zippers according to the purpose of using.

1. Auto-lock Slider:

As we have discussed above in auto-lock sliders, the slider position is fixed, it does not goes up or down. Now let us look closer into it.

Auto-lock sliders are manufactured with a small pin just below its puller which is placed between zipper teeth. That pin is connected to zipper puller. So, in that case when we use the slider up and down, the puller the pin goes up and we could freely move the slider. But when we are not using the zipper, in that case the puller is not touched and the pin goes in the zipper teeth and the slider can’t be moved up or down. So that means it is locked. So, this is how the auto lock sliders works. Until we touch the slider and move it up or down the pin is placed between the teeth in that case the slider position remains unchanged. If we start using the zipper the pin comes out from the zipper teeth and we can easily move the slider.

Different Slider Locking pin and pullers for more components please visit: https://www.qlqcompany.com

We can also divide Auto Lock Slider based on component.

1.1 Five-Component Auto Lock Slider:

This auto lock slider consists of 5 Major Parts- Cap, Cap Spring Pin (to lock the zipper), Slider Body, Pullers, Needle to lock or unlock the slider. This kind of zippers are very strong compare to others.

1.2 Three-Component Auto Lock Slider:

This auto lock slider consists of 3 Major Parts- Cap Spring Pin (to lock the zipper), Slider Body, Pullers or slider hook. Which makes it strong.

2. Semi Auto-lock Slider:

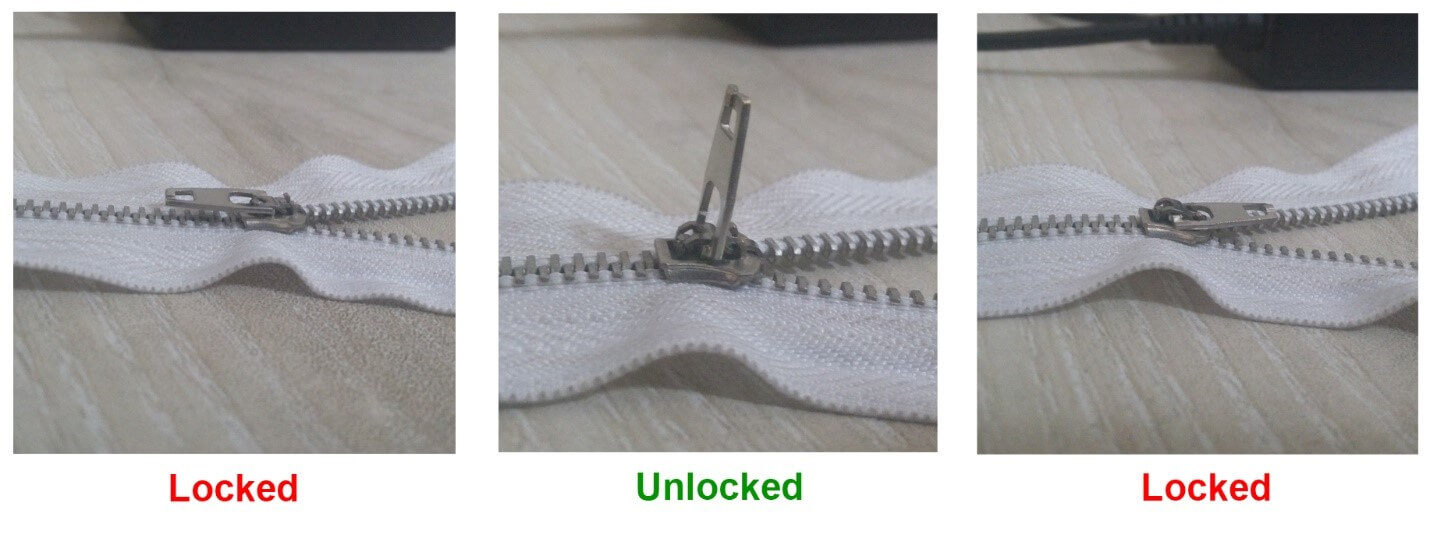

Semi auto-lock sliders works in a way where, the slider behaves like auto lock and non-lock based on slider puller position. Here is the basic structure of that kind of slider.

In this type of zipper, the Pin is designed in a way that it can detect the puller position and makes the slider locked or unlocked. For example.

So here in picture marked as “Locked” the puller is parallel to the zipper tape. In that case the pin is between the zipper teeth. When the Puller is in vertical position in the picture marked “Unlocked”

We can move the slider freely.

3. Non-lock Slider:

Non lock sliders do not have any controller pin inside its body. Its puller us free and the slider can be moved anytime in any direction.

Usage Of different types of zippers

Auto-lock sliders: garments, sportswear, outerwear, jackets, skirts, dresses, etc.

Non-lock sliders: bags, handbags, luggage, tents, bed covers, etc.

Semi-auto lock sliders: jeans and pants

Related Posts

-

Blog & NewsQLQ Wish All Mothers A Happy Ho

…

Mar 08, 2024

-

Blog & NewsNurse's Day

Whispering is your character, white clothes and white skirts are your characteristics, rescuing the dead and healing the wounded is your bounden duty, nursing patients is your sacred duty, you give patients selfless love, and you turn your…

May 12, 2022

-

Blog & NewsEid Mubarak

Although now we are going through a hard time because of covid -19, but we all believe everything will goes well soon. QLQ family wish you and your family all the best!…

May 05, 2022

-

Blog & NewsHow To Produce Invisible Closed

Our invisible zipper advantages: 1) The standard reciprocating fatigue of invisible zipper is ≥600 times, but our invisible zipper can reach ≥900-1200 times. 2) The standard tension of invisible zipper is ≥480N, but our …

Apr 22, 2022